Internal Combustion Engine, the short and most popular name, is IC Engine. It is one of the types of engines where fuel burns and creates pressure on the piston inside the cylinder. Fuel burns or combusts inside the cylinder; that’s why it is known as an internal combustion engine. The IC engine is the most important topic for mechanical engineering and the automobile stream. Almost everyone has an idea about the IC engine. Nowadays, these engines are the largest power-generating engines. The type of power generated may be mechanical power or electrical power.

Before we read about IC engines, we will also learn about heat engines. Because the IC engine is a type of heat engine,

Page Contents

What is a Heat Engine?

An engine is a machine that can convert one form of energy into another in the desired manner. A heat engine is a machine that transforms chemical energy into thermal energy, and this thermal energy produces mechanical energy. Here, chemical energy is obtained from burning the fuel. Where fuel is like wood, coal, petroleum fuel, etc. Heat engines are classified into two major types:

- External Combustion Engine

- Internal Combustion Engine

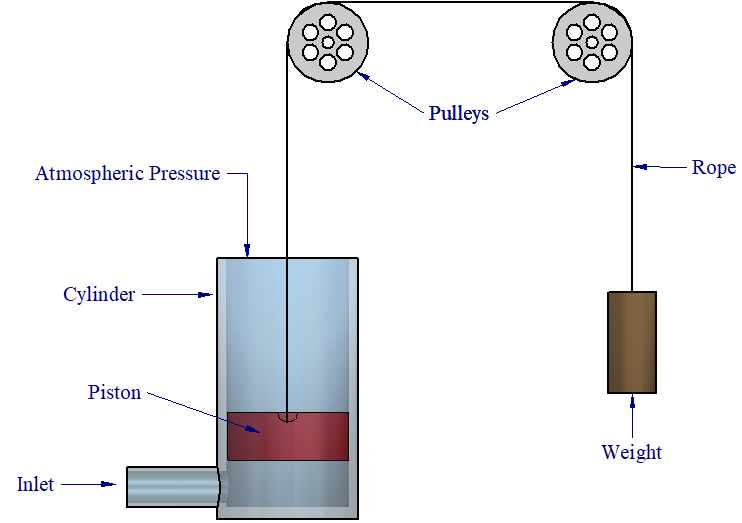

Do you know about the Steam Engine? Who invented the steam engine? The steam engine was invented by James Watt. The steam engine is a perfect example of an external combustion engine. In an external engine, the mixture of fuel and air combusts outside and transfers heat to the second fluid. This fluid is the working fluid for the cycle. The steam of the working fluid pushes the piston. A stirring engine is also an external combustion engine.

Also Read:

- Which side your car’s fuel cap?

- Best Mechanical Engineering Project ideas

- How a Injection moulding machine works?

What is an IC Engine?

The internal combustion engine, in this type of heat engine the fuel and air mixture ignite and directly, pushes the piston. Diesel and gasoline engines are the best examples of internal combustion engines. The Wankel cycle, gas engines, rocket and jet engines are also examples of internal combustion engines.

As per design considerations, the IC engines are compact and lighter as compared to external combustion engines. That is the main reason these engines are widely used in automobiles and transport vehicles like cars, buses, locomotives, aircraft, etc.

The earliest IC engine was Huygens Gunpowder Engine. The internal combustion engine was invented in 1680 by the famous Dutch physicist Christian Huygens.

IC Engine Parts:

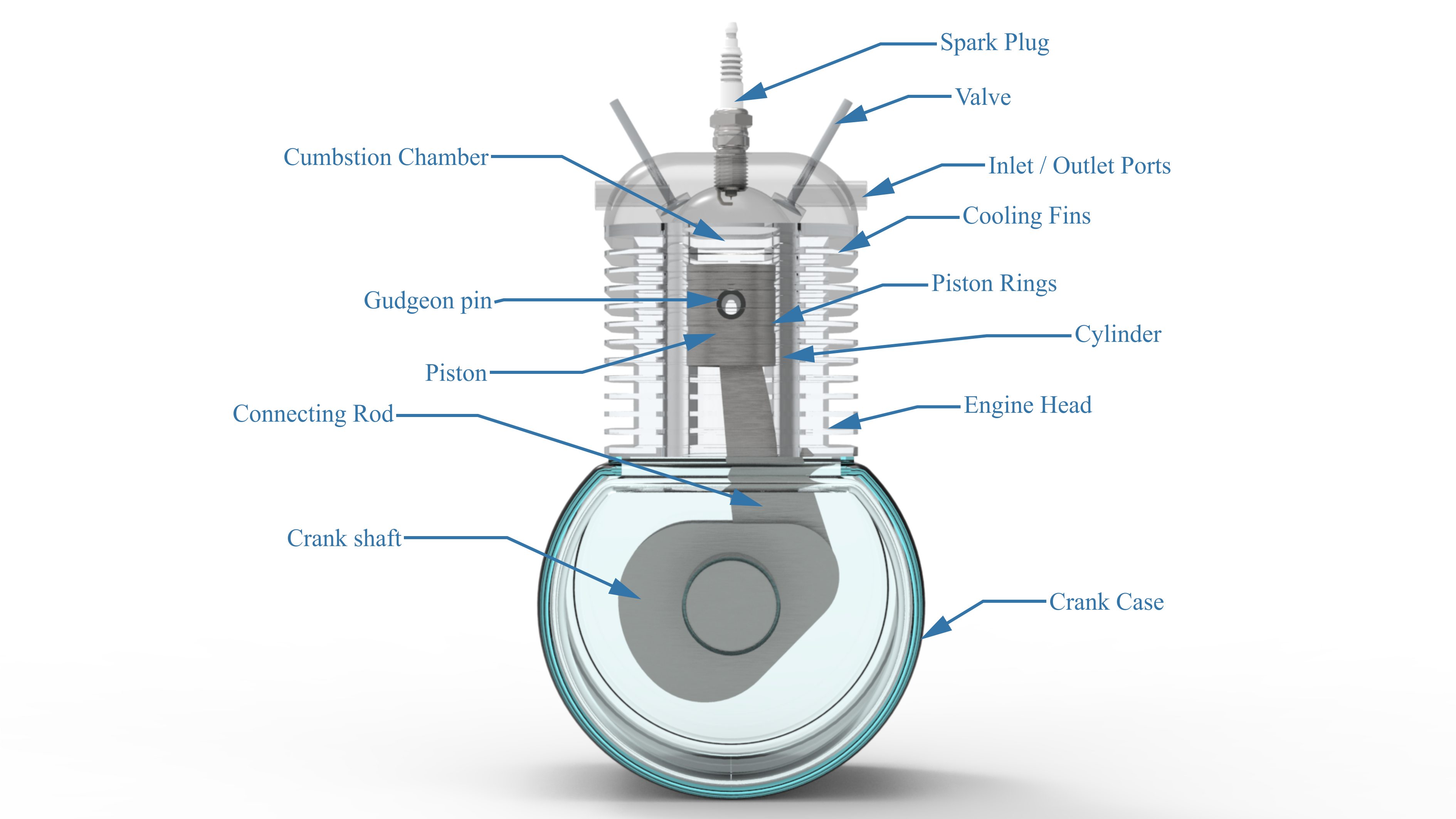

Let’s check out the basic parts of a single-cylinder spark-ignition engine (SI engine). In the below image, you can see a sketch layout of a single-cylinder engine. The cylinder block holds the cylinder. And the cylinder head covers the top end. In the cylinder, a piston moves upward to downward and vice versa. This motion is a reciprocating motion. The space enclosed between the upper part of the cylinder and the top of the piston during the combustion process is known as the combustion chamber.

The mixture of air and fuel enters the combustion chamber through the inlet port. This charge (air and fuel mixture), before entering the inlet port, comes from the carburetor to the inlet manifold. The inlet manifold is a connector between the air intake and the inlet port.

What is the function of the carburettor? Do you know?

The carburetor is a mixing, regulator, and controller device. This means the carburetor makes a mixture of fuel (gasoline) and air. The carburetor regulates the air-to-fuel ratio. And it also controls the engine’s speed by regulating the air-fuel mixture with the help of a throttle.

The inlet valve in the cylinder head charges the air-fuel mixture in the combustion chamber, and the exhaust valve discharges the combusted product after combustion.

To start the combustion, the air-fuel mixture requires a spark. A spark plug provides this spark to initiate combustion.

After the combustion process, gases expand and create a force on the piston. This force displaces the piston downward. A couple of rings, i.e., piston rings, prevent gas leakage while expanding the gas. And a gudgeon pin provides smooth swivel motion between the piston and crank rod.

Piston’s downward movement rotates the crankshaft with the help of a crank rod. The crank rod or connecting rod helps to convert reciprocating motion into rotational motion. And crankshaft is a translator, which translates the reciprocating motion into rotational motion. The crankshaft is enclosed in a crankcase. It is the main engine body. Inside the crankcase, the crankshaft is supported by bearings.

From which part of the engine operates the valves? Did you think that?

Now, let’s go back to the combustion process. Here, the charge intakes through the inlet valve and the combusted product discharge from exhaust valves. Both, the intake and exhaust valves are operated by the valve mechanism. The Crankshaft also drives the camshaft with the help of timing gears. This camshaft transform motion to the pushrod and rocker arm for opening the valves. The valve springs develop force against the rocker arm force and this closes the valves again.

Engine parts are made from what kind of materials?

Did you think what is material used to make pistons? Let’s we will take a short time to know that material. Not only for piston, but we will discuss in a brief about materials of other engine parts also.

|

Engine Part Name |

Material |

Manufacturing Method |

| 1. Cylinder head | Aluminium alloy, Cast Iron | Casting, forming |

| 2. Cylinder | Cast Iron | Casting |

| 3. Piston | Aluminium alloy, Cast Iron | Casting, forging |

| 4. Piston rings | Silicon Cast Iron | Casting |

| 5. Gudgeon (Piston) pin | Steel | Forging |

| 6. Valve | Alloy Steel | Forging |

| 7. Connecting rod | Steel | Forging |

| 8. Cylinder liner | Nickel-based alloy, Steel, Cast Iron | Casting |

| 9. Bearings | Bronze alloy, White metal | Casting |

| 10. Crankshaft | Alloy steel, Ductile (Nodular) cast iron | Forging |

| 11. Crankcase | Aluminium alloy, cast iron, alloy steel | Forging |

| 12. Rocker arm | Cast iron, carbon steel, aluminium alloy | Forging, casting |

Terminology in IC Engine:

The following terms are used in the IC engine.

- Stroke (L) – The distance travelled by a working piston in a cycle.

- Piston Area (A) – The cross-sectional area of the piston.

- Cylinder Bore (D) – The nominal inner diameter of the cylinder.

- Dead Center – The position of the piston during working either at the topmost point or bottommost point of the cylinder. In an engine, there are two dead centers i.e; Top dead and Bottom dead center.

- Top dead center (TDC) – The furthermost or topmost position of the piston with respect to the crankshaft is the top dead center. TDC is known as inner dead center (IDC) in the case of horizontal engines.

- Bottom dead center (BDC) – The bottommost or nearest position of the piston with respect to the crankshaft. TDC is known as outer dead center (ODC) in the case of horizontal engines.

- Displacement Volume (Vs) – The volume generated by the piston when travelling between one dead center to another dead center. It is the product of the piston area and stroke. Another name of displacement volume is swept volume.

Vs = A x L

- Clearance Volume (Vc) – While the piston goes on TDC, the volume of the combustion chamber is clearance volume.

- Cylinder Volume (V) – The total of displacement volume and clearance volume.

V = Vs + Vc - Compression ratio (r) – The compression ratio is the ratio of the cylinder volume and clearance volume.

r = V / Vc

Conclusion:

In this article, we have read about the Heat engine and IC engine, The general parts, and the terminology of the engine. In the next article, we will also discuss the base of classification and types of IC engines. Till stay continues with us.

If you have any queries regarding this article, please comment in the comment box. Your review will help us to improve content quality.