Page Contents

What is Sheet Metal?

A piece of metal that can be formed into a thin sheet is called sheet metal. Sheet metal is one of the basic metalworking that can be trimmed and bent in various shapes. There so many different types of metals that can be formed into a sheet. Some examples are Aluminium, steel, copper, tin, brass etc widely used in industries. Some precious metals such as gold, silver, platinum are also used as sheet metals for special purposes. In our daily life, there are uncountable products we use which are made of sheet metals. Sheet metal is used in Automobiles, Aerospace, Construction and various industries. There are various types of sheet metal operations for making products various. Some basic operations list is below.

- Blanking

- Punching

- Piercing

- Cut-off

- Parting off

- Notching

- Bending

Let we will discuss the types of sheet metal operations in detail.

What Are the Basic Properties of Sheet Metal?

Before we read the sheet metal operations in detail, we must have to get familiar with the sheet metal properties. Every metal has unique properties that give it’s a unique identity. Like gold has a higher density, that’s why it is heavy metal than others. And it is softer than other metals as well. Some metals having the ability to drawn into the wire that metals are known as ductile metals. And this characteristic is known as Ductility.

Like ductile metals, the ductile materials are rolled or hammered into a thin sheet in some special cases. This property of the material is known as Malleability. So, malleability is the property of the material that gives an identity of sheet metal. the sheet metal or malleable material should be plastic but not compulsory to be so strong. And this is the main characteristic of sheet metal.

All sheet metals having basic mechanical properties like Tensile strength, shear and bending strength, compressive, yield strength and hardness.

What are the Sheet Metal Operations?

Also Read:

- Hydrogen Fuel Cell Cars: A Closer Look at the Technology

- Which metal is been used to make Cybertruck’s robust skin?

- What is Lean Manufacturing?

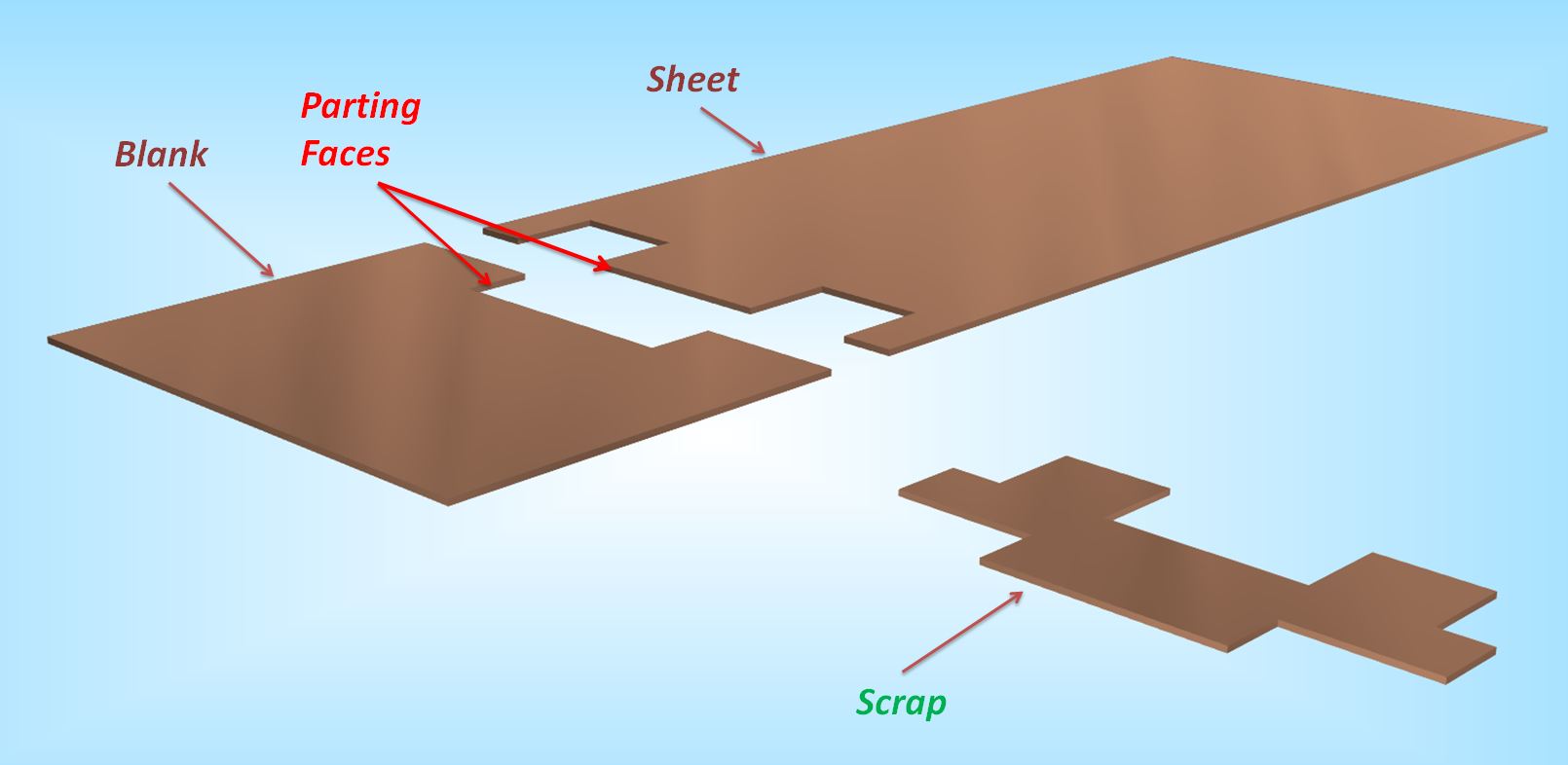

1. Blanking:

Blanking is the process of producing flat pieces from a large sheet. Only a small amount of sheet metal will be processed as a finished product or part over the larger sheet area in the blanking process. In this process, enough residue will remain. This process is done with the help of punch and die. The blanking process is used to manufacture various parts in automobiles, such as doors, hoods, lids, BIW components and etc. And in other industries like utensils, jewellery, electrical components etc., the blanking process is used.

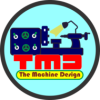

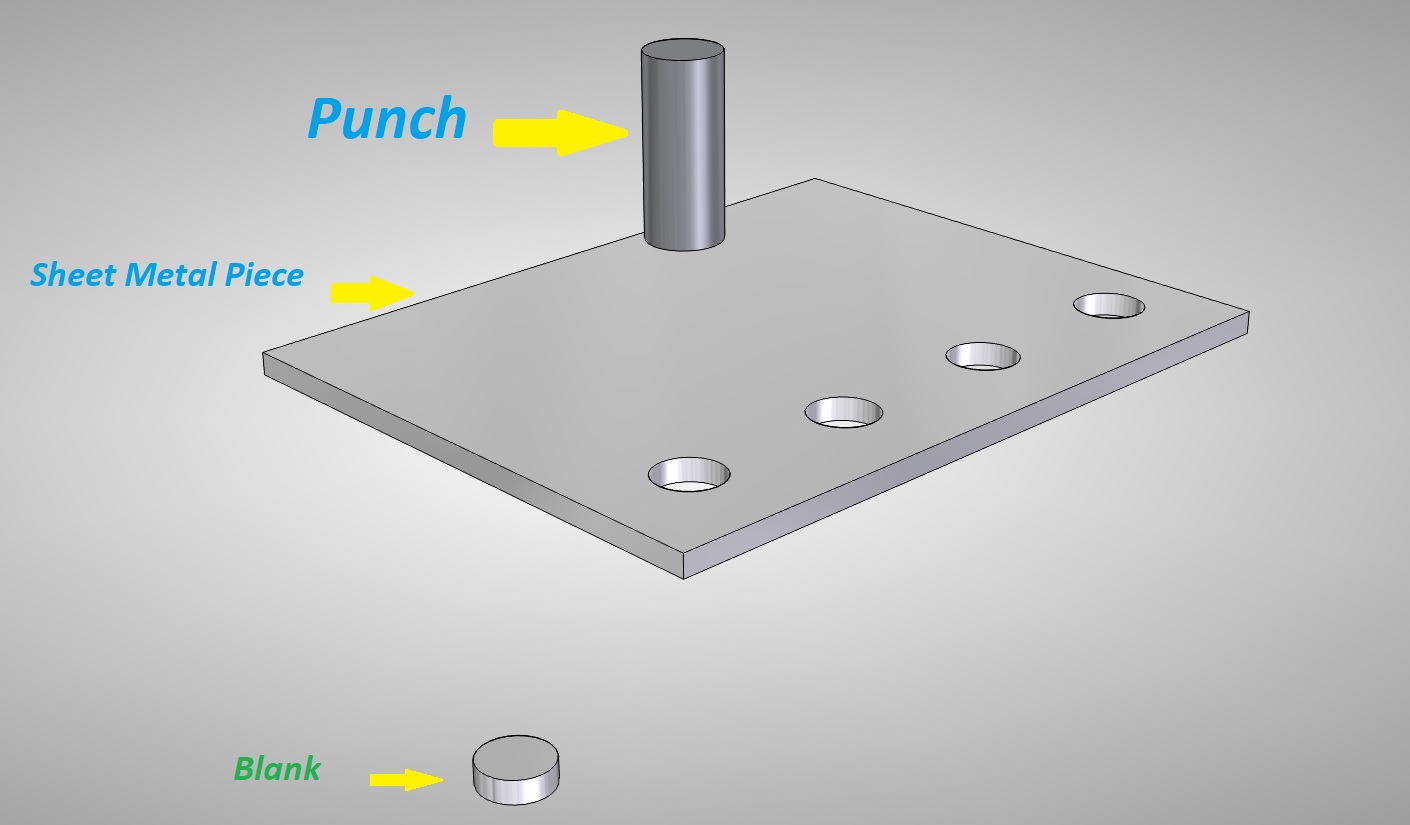

2. Punching:

The punching operation is vice versa to blanking. In this operation, extra (scrape) material removes from the raw sheet. This operation also performed with the help of die and punch. But here the punch removes scrap. This process is used to create holes and cutouts in the sheet.

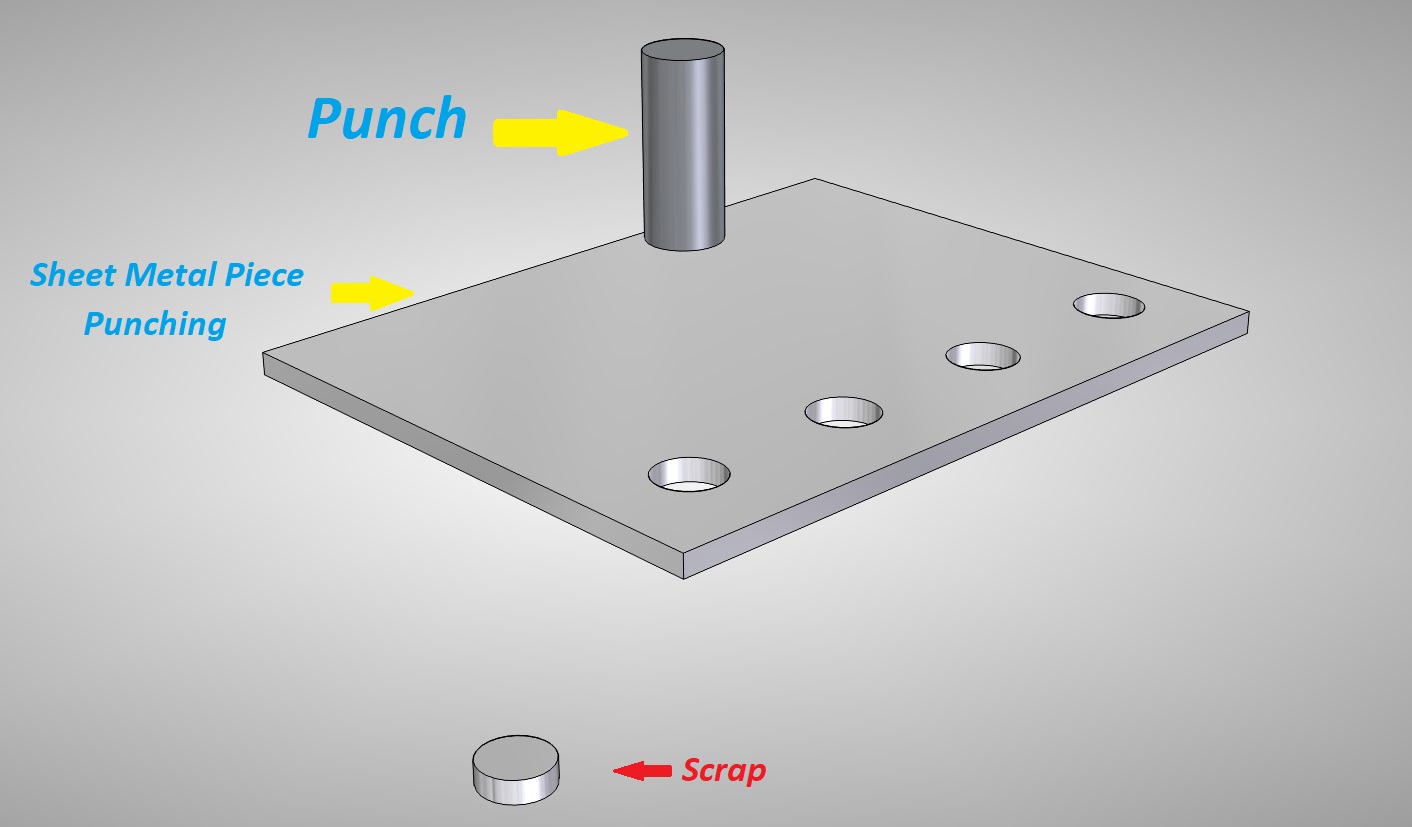

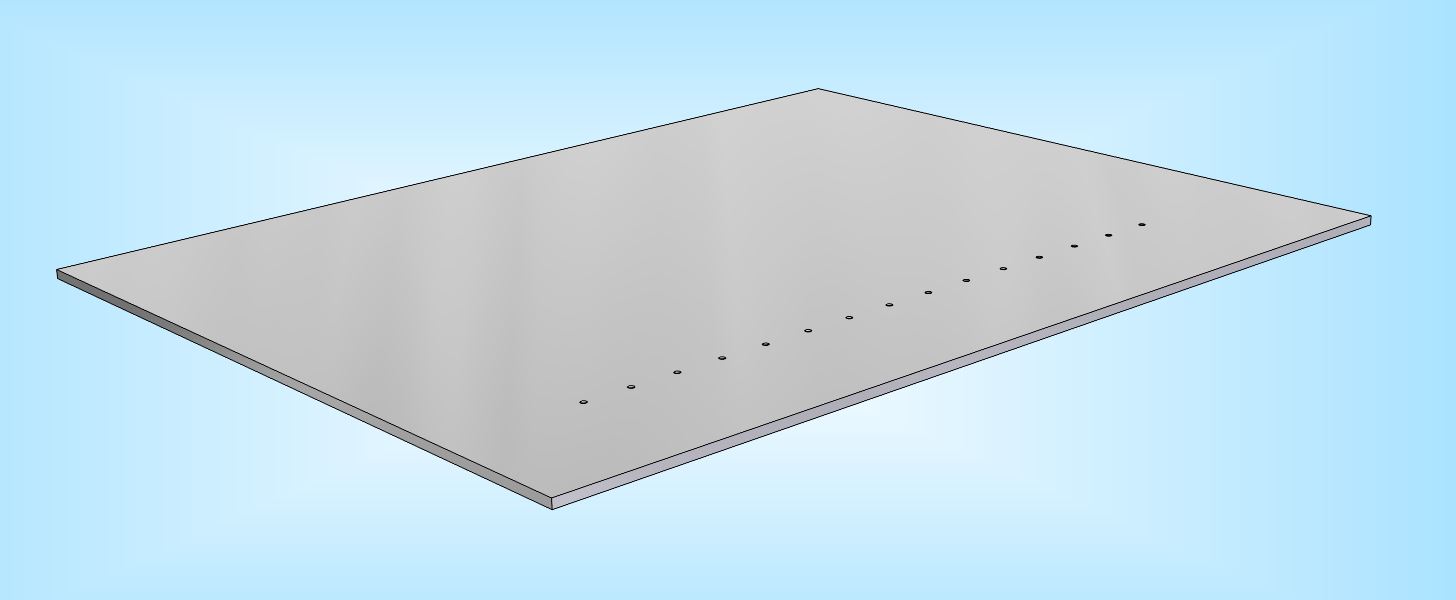

3. Piercing:

The word piercing means pinning any tool in the workpiece or sheet for creating circular or other shaped holes. Almost no scrape will be created in this operation. Creating a hole in paper using a pen or any sharp tool is also known as piercing. The piercing operation for sheet metal is also similar. For this operation, a blanking punch is used.

Also Read:

- Injection Molding Machine.

- What is IC Engine?

- Sustainable Office Furniture: Creating an Eco-Friendly Workplace

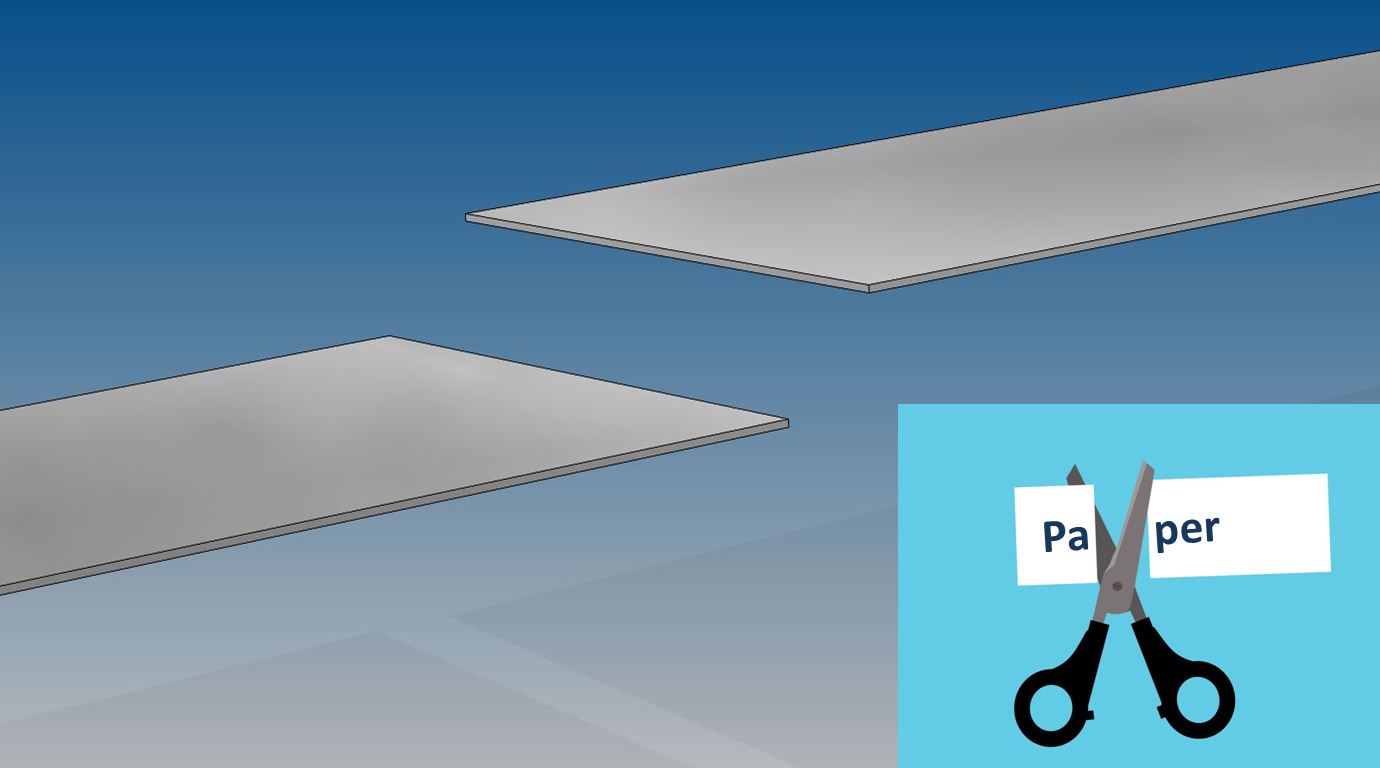

4. Cut-off:

This operation separates the work material along a curve (which may be a straight line or irregular single curve). That’s why in the Cut-off operation no scrape will be created. For example, cutting a paper into two pieces using a seizer.

5. Parting off:

The parting off operation is also similar to the cut-off operation. But here scrape will separate from the blank piece. This is the reason it is the next best method for cutting blanks.

6. Notching:

Notching operation is to cut out a portion of the sheet from its sides. And in semi notching operation metal cutting out from inside of the sheet. Sometimes, notches applied for stress relieving during the bending. So, notches created before the bending operations.

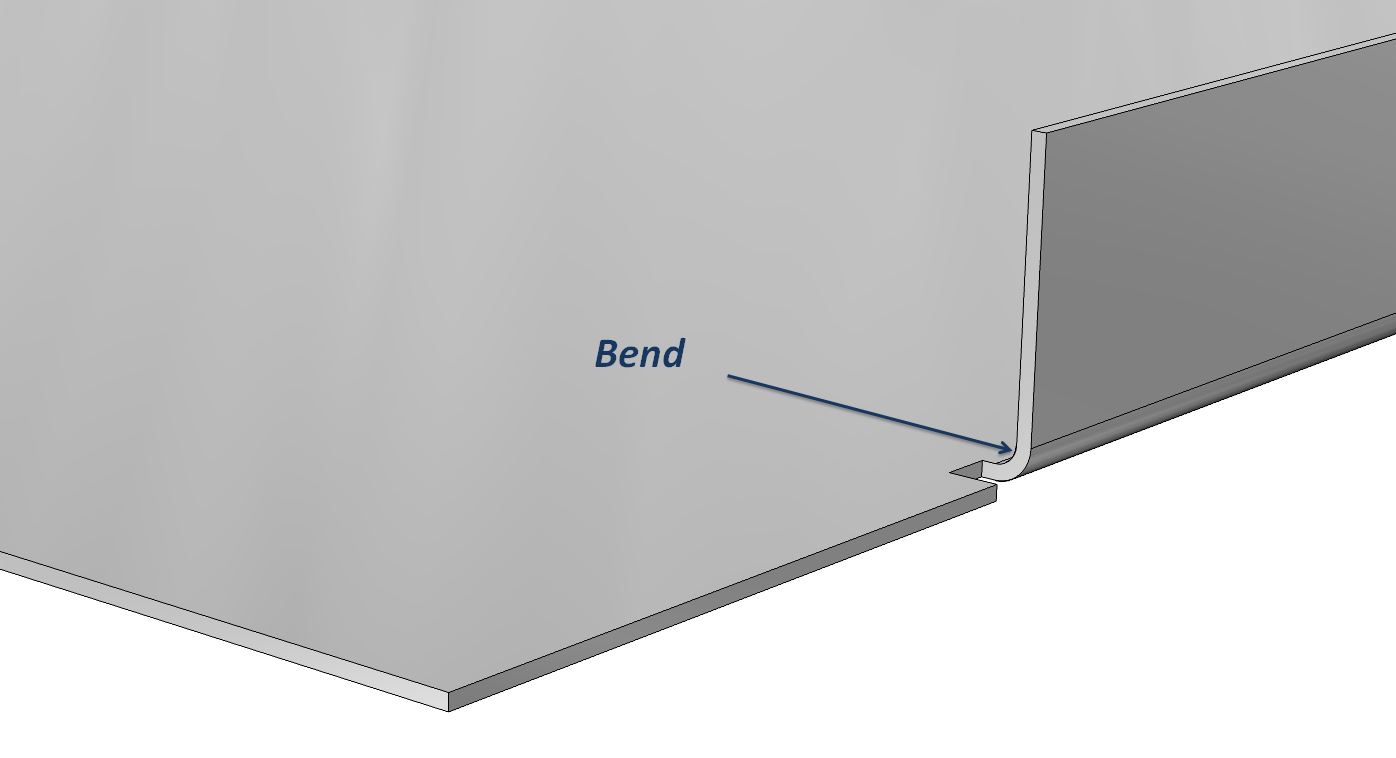

7. Bending:

Bending operation is used to creating a bent shape around a straight axis. A punch applies stress more than the elastic limit but less than the ultimate tensile strength. Hence, a permanent contour occurs due to that stress. This angle may as per requirement.

Further, There are kinds of bending operations.

- V-Bending

- U-Bending

- Edge Bending

- Channel Bending