We are all living on Earth. In this world, to live a better life, we need the three most important things. These things are food, clothes, and home. Among those three things, home is the most important. But have you ever thought about what is most important that helps to make our home, building, or any other structure? Your answer will be sand, stone, bricks, concrete, steel water, etc. But one thing that bonds all materials together is cement. In our daily lives, cement has a very important role. We live in the house, walk on the road, and travel through bridges. Every building, road, airport, and many other structures require cement for construction.

But did you think that cement comes from where? What is cement made of? How is it manufactured? Let’s talk about all related topics to cement. What is Cement and How it is Manufactured?

Page Contents

What is cement?

Cement is a binding substance used to bind other buildings or civil construction materials like bricks, stones, gravel, tiles, etc. Cement can be set and hardened independently and can bind other building materials together. It is a very fine powder containing limestone, clay, silica, and alumina. Also contains bauxite and iron oxide. All these contents are blended and heated to 1200°C to 1500°C; this process makes clinker. Then grind this clinker into a fine powder. Also added Gypsum for providing settle time.

History of Cement:

Humans have started using cement material in construction. Even we can say that cement material history is old, like engineering and construction history. The archaeologist has discovered some kinds of cement material used in the Harappa and Mohanjo-Daro civilizations during excavation. In the past, the Greeks and Romans used burning limestone as cementing materials. Later, they had increased awareness of volcanic ash and tuff, mixing with limestone powder and sand, which provide better strength and durability in water.

The Romans had found volcanic tuff near Pozzuoli village in Italy. The obtained ash contained better siliceous, due to this natural quality, it is named Pozzolana. Later, this name was added to other artificial and natural cement materials with similar properties.

Accidentally, the Romans discovered that adding blood to a cement mixture would increase durability and workability. Hemoglobin has better plastic properties. It was another reason for the durability of Roman structures.

Also Read:

- What is Wrench and Its Uses?

- 7 Steel Storage Racks for Industrial Workspaces

- Petroleum: Source, Formation and Classification

Facts About the Cement:

William Aspdin had invented “Modern portland cement”. And patented on 21st October 1824.

China is the World’s largest cement producer country. 2200 Million Metric Tonnes of cement were produced in 2019. Over half of the cement is produced in China.

India is the World’s second-largest cement producer country. 320 Million Metric Tonnes of cement were produced in 2019.

The world’s largest cement plant is in Michigan. Currently, this plant is part of the world’s largest producer company Lafarge Corporation.

Do you know???

The world’s tallest statue “Statue of Unity” is situated in Gujarat, Bharat (India). This statue is built to tribute to “Iron man of India – Sardar Vallabh Bhai Patel. This statue is 30 meters taller than the previous record-holder statue “Spring Temple Buddha” in China. To construct the Statue of Unity, 210,000 m³ cement used.

What are the types of cement?

There are various types of cement to fulfill specific requirements in the construction industry. These types are based on the use of additives, various types of raw materials in mixtures, and variations in chemical composition.

Cement

- Ordinary Portland Cement – Grade 33, Grade 43, Grade 53.

- Rapid Hardening Cement –

- Extra Rapid Hardening Cement

- Sulphate Resisting Cement

- Portland Slag Cement

- Quick Setting Cement

- Super Sulphated Cement

- Low Heat Cement (Fly ash based cement)

- Portland Pozzolana Cement (Calcined clay-based cement)

- Air Entraining Cement

- Coloured Cement (White Cement)

- Hydrophobic Cement

- Masonry Cement

- Expensive Cement

- Oil Well Cement

- Rediset Cement

- Concrete Sleeper Grade Cement

- High Alumina Cement

- Very High Strength Cement

Portland cement is classified under the ASTM (American Society for Testing Materials) standards. According to ASTM, cement has Type I, Type II, Type III, Type IV, Type V some other minor types.

What are the Main stages of Cement Manufacturing?

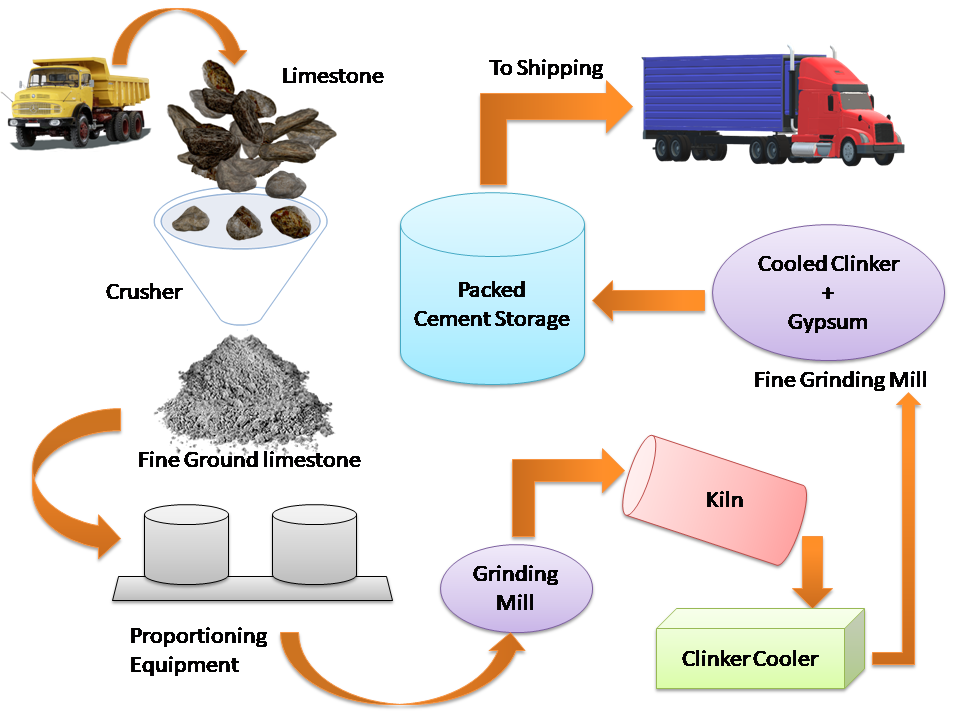

To make cement in a cement production plant, there is a standard process. The first step of the process is quarrying and raw materials are prepared. In the second step, the mixing of raw material (clay and limestone) in a certain proportion. Then this mixture is burned OR heated in a furnace (kiln) to make a clinker at a temperature of about 1300° to 1500° C. This step is known as the clinker production step. And in the third stage, this clinker is cooled and mixed with gypsum then ground into a fine powder which is the final product as cement. Let, we will see a cement production process on a flow chart. Before it, also we need to get familiar with types of cement processes.

What are the types of Cement manufacturing processes?

Here are the three main types of cement processes. i.e,

- Wet Process

- Dry Process

- Semi-dry or Pre-calcinar Process

Wet Process:

In the wet process, the limestone is brought from the quarry and crushes into a small form. Then it is mixed with clay and ground into fine powder in a ball mill or tube mill. And mixed it with water. This makes a fine consistency slurry. The slurry is pumped into a slurry tank. To prevent the settling of limestone and clay particles, the slurry is stirred with a rotating arm or chain in slurry tanks.

This slurry was sprayed on the kiln’s outer surface. The heated kiln surface removes moisture contents from the slurry and converts them into flakes. These flakes go to the hottest part of the kiln. Where temperature ranges from 1300° to 1500° C. At this temperature, the material gets diffused. And chemical reactions occur in diffusion. Where, the silica, alumina, and lime get combined. This combination turns into a grain size of 3 to 20 mm known as clinker. The cooled clinker fine ground in a ball mill with mixing gypsum into. Now, it is ready for packaging.

The main advantage of the wet process is, it is more accurate and easy in controlling the mixing and grinding of raw materials. But, it requires vast fuel to remove water content from the slurry.

Dry Process:

In the dry process, the raw materials are ground in a grinding mill and charged in the correct proportion. This raw material mixture is ground in very fine powder in the grinding mill. This fine powder is the raw meal. And it further ground and mixing of the corrected amount of its contents by pressurized air. And this powder also contained dry air, it behaves like a fluid.

Now, this blended powder is filtered and fed into the granulator. Here, 12 per cent by weight of water is added in fine powder to make small pallets. It helps in chemical reactions while heating in a rotary kiln. In the dry process fuel (coal) is required lesser than the wet process. So, it is an economical process.

For the semi-dry process, the same method was used. The semi-dry process also required less amount of fuel (coal). It allows for a higher production rate.

Conclusion:

In this article, we have studied Cement, its history, types, manufacturing process, and process types. We will discuss in detail cement manufacturing plants and machinery in the next article.

If you have any queries regarding this article, please comment in the comment box. This article is helpful for you? Please like and share it. Your review will help us to improve content quality. If you have any queries regarding this article, please comment in the comment box. This article is helpful for you? Please like and share it.

Nice content.

Thanks.